Leaky oil seals – a problem for many old vehicles. Rubber material in O-rings hardens over time, leading to a loss of compression and to oil leaks in other parts of a vehicle. Why does this happen? What can we do to prevent it happening?

Rubber and neoprene material hardening in seals and O-rings is caused by elastomer hardening, evaporation of plasticizers, and oxidation that brings on cracking. This is in turn often caused by excessive temperatures. As oil quality deteriorates with time and shear stress friction increases, thus raising the temperature to that excessive level.

What can we do?

First, oil quality should be boosted. This is the function of SOD-1 Plus. Its triple-ester makeup provides adsorption – an extra-thick layer of lubricant sticks to metal surfaces – and it strengthens the molecular structure of the base oil. This renders the base oil stronger under pressure. The result is a lower temperature because friction is greatly reduced.

Second, because SOD-1 Plus has a lower surface tension than base oil it penetrates the tiny cracks and fissures in the seal material and re-elasticizes the material – it softens the rubber and allows it to expand again, thus sealing off any spaces through which oil might leak or compression might be lost.

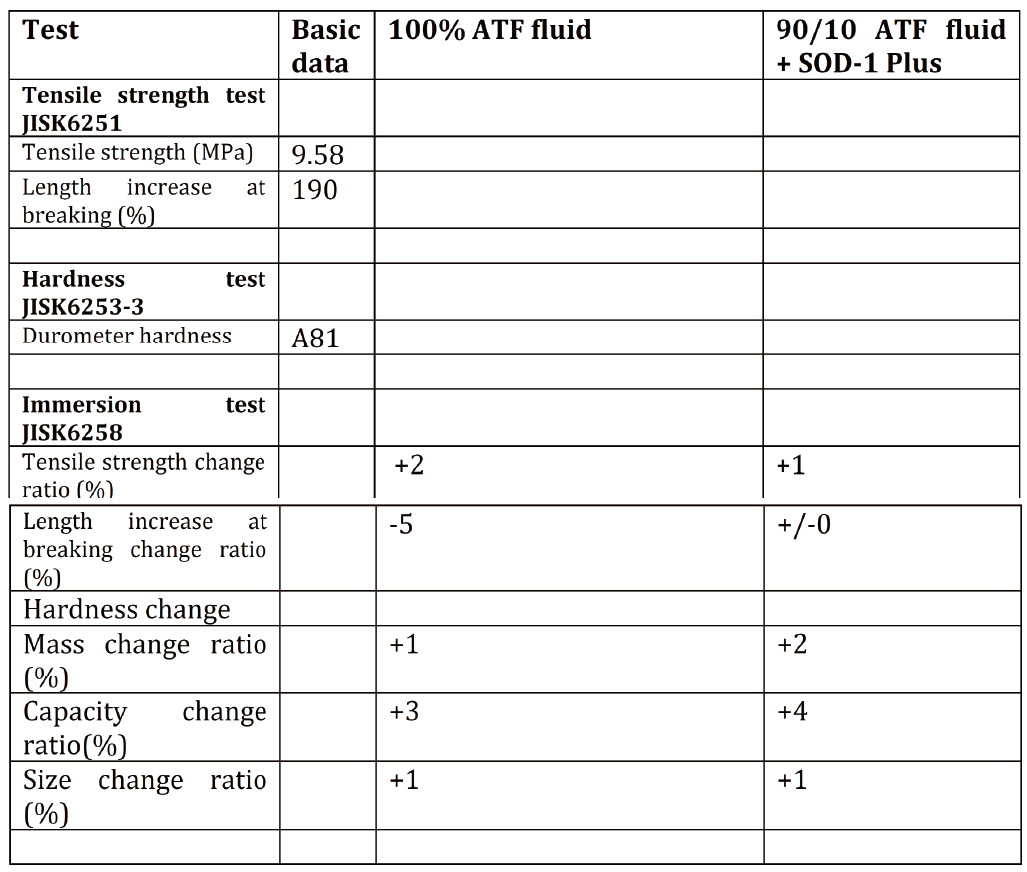

To test the effect of SOD-1 Plus on rubber seal material we asked the Japan Analyst laboratory to run a test for us in 2015. The material used was a rubber automatic transmission seal. Section of the seal were immersed in two solutions for 72 hours and then tested. The first solution was 100% ATF fluid; the second was 90% ATF fluid and 10% SOD-1 Plus. The results were as follows: