Benefits & Data

Shell 4-ball Wear Test

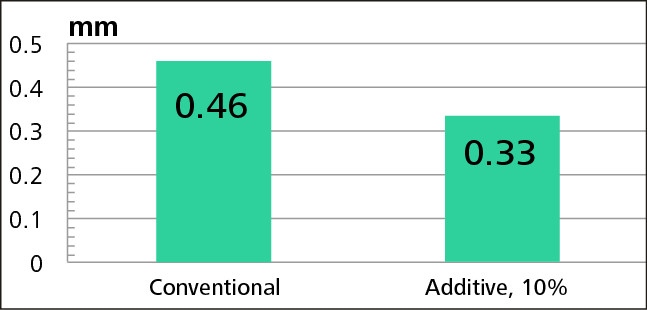

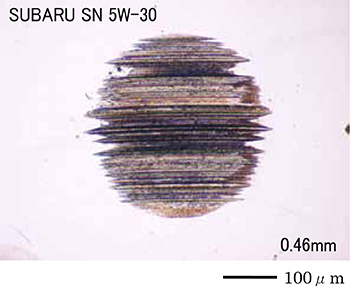

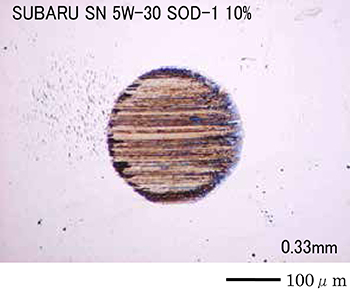

Also noteworthy is the result of the Shell 4-ball wear test. This measures the characteristic of SOD-1 in improving friction and abrasion of metal surfaces. This test was originally developed to assess the capability of lubricating oils to prevent wear in highly loaded contacts such as ball bearings. The test apparatus contains three stationary balls where one rotating ball is pressed against them. Torque, friction, oil temperature, and rotational speed and time are set, and the wear scar diameter on the ball bearings is recorded as a measure of the oil’s lubrication performance.

Using a 5W-30 lubricating oil, in this test of SOD-1 the professors used a rotational speed of 1200 rpm, a load of 40 kgf, a temperature of 75C, and a time of 60 mins to compare the 5W-30 oil on its own with 5W-30 combined with 10% SOD-1. Once SOD-1 was added it reduced the wear scar by 28.3% (0.33mm compared to 0.46mm without SOD-1).

CONVENTIONAL OIL

ADDITIVE OIL (10 VOL.%)